By now you will surely have heard about the Proudly South African 500cc 2-stroke engine being made for the Roof Of Africa. At the beginning of the year we had a chat with Mr Koos Zietsman about this seemingly improbable, impossible mission – and we left that story wondering whether it would all be done in time. In case you missed our first feature, click here.

Well guess what? The engine has been made. Yes made. Not built. Manufactured and assembled to Koos and the team Matjien’s specifications. It’s been a labour of love – and over the last few months we have watched the progress and determination behind this project. In this feature you’ll see references to the Bonneville bike. this is mostly about the Roof bike, but, of course, they have been working on two projects simultaneously.

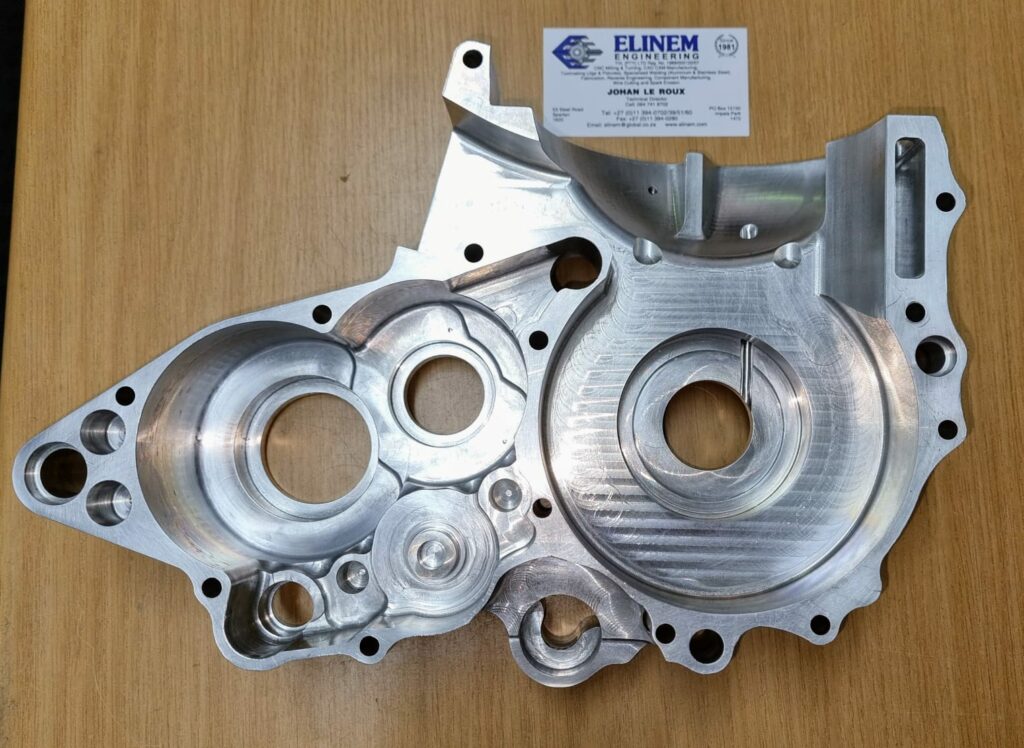

“Here’s a short story of what is possible if you get the right people together and let them loose to do something amazing: we received funding for the PZ engines on 25 February. We had nothing to start with except this huge dream and a bucket full of enthusiasm and now, only 7 1/2 months later, we start to build PZ490 for the Roof. We received the beautiful billet machined casings from Elinem Engineering on Friday and the crank from P&C Technologies on Saturday, here we go!”

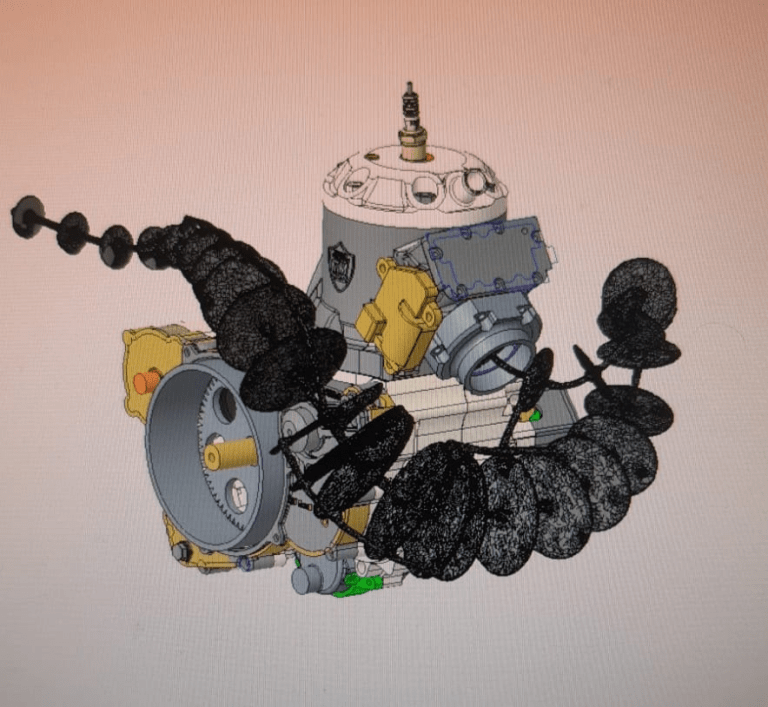

Each 3D plastic component is checked, miked up and assembled. this is the first time the starter was tested.

Just yesterday we woke up to the news that the engine is complete – and is now ready to be slotted into the frame…

It’s a good story – and we cannot wait to actually see it run next weekend at the unveiling of the bike.

But here’s a little bit of a pictorial about what it takes to actually manufacture a motorcycle. If you have a single technical bone in your body, you have to agree that it’s pretty flippen amazing!

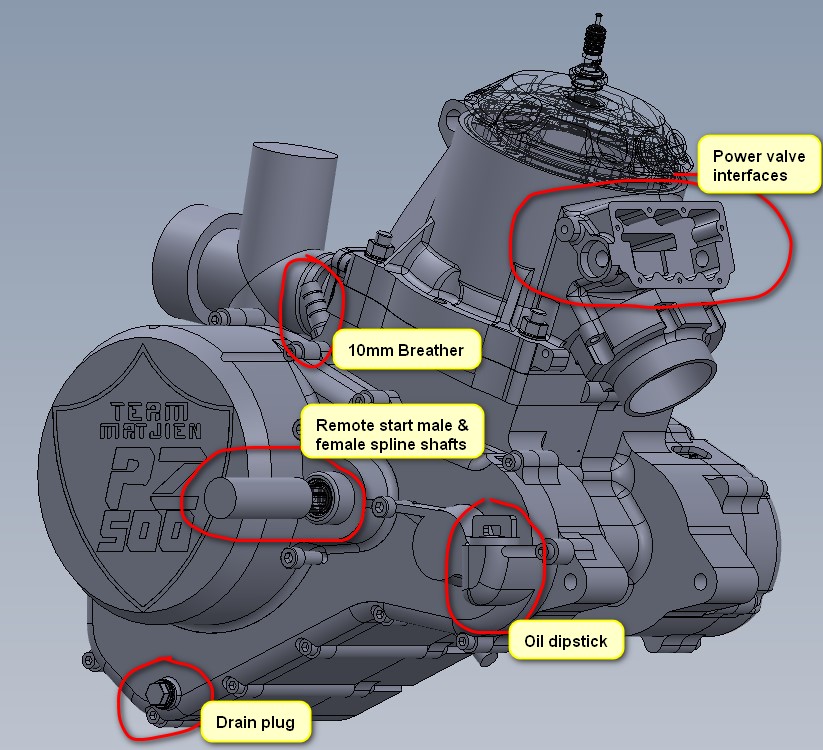

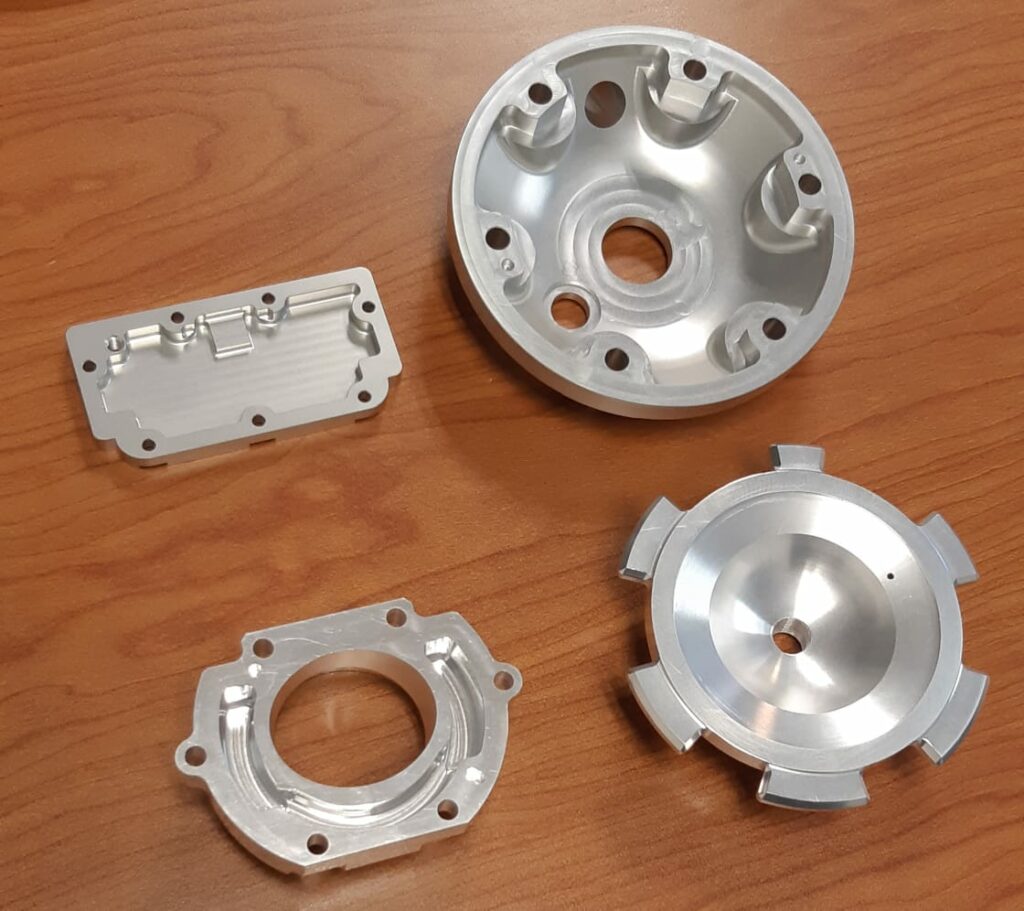

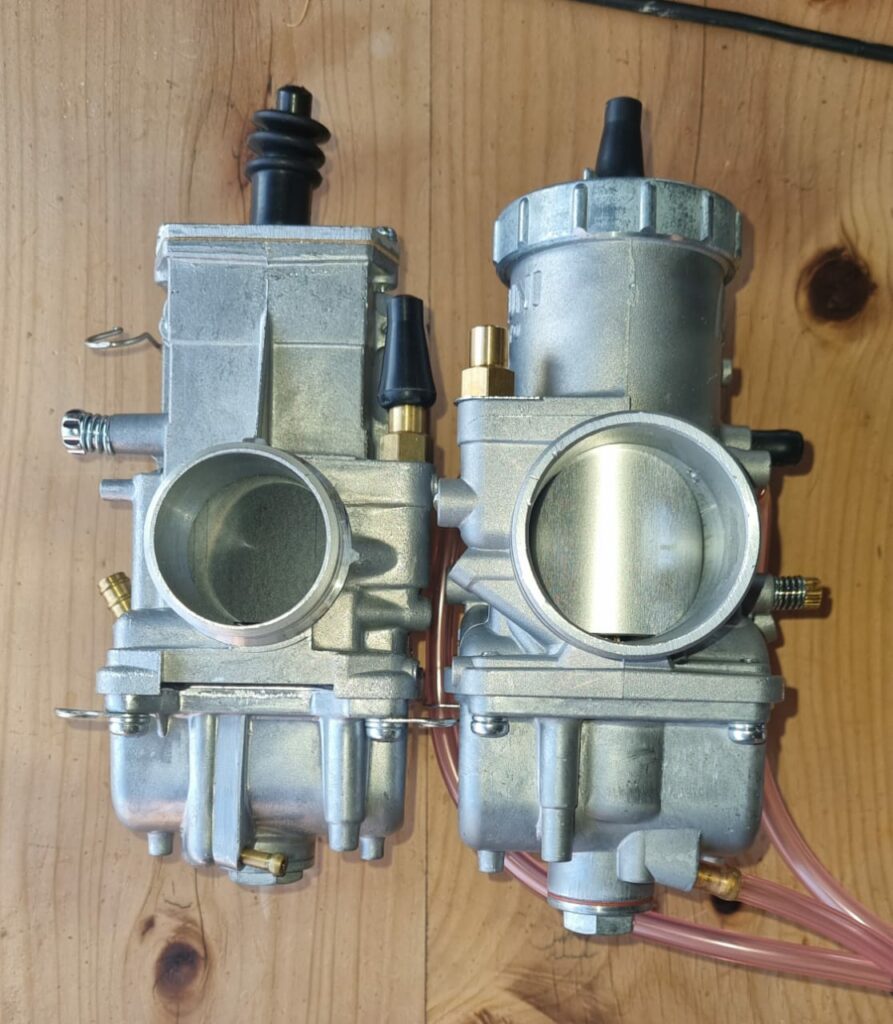

The challenge was a significant one; “At the moment we’ve got the 2-part head being machined in China, primary drive and balancer gear being finished in the UK, crank being machined by P&C Technologies, casings by Elinem Engineering, barrel by Rost Engineering and balancer shaft and counterweight by Micromax, intricate small parts being 3D printed in S/S by Build Volume. We’re spreading the load and doing what we can to get all the parts done ASAP!”

“I collected both normalised PZ490 and PZ500 crank halves from Bohler heat treatment and dropped them off at P&C Technologies this morning to start the next round of machining before final heat treatment and grinding, progress! The two halves on the left are for PZ500, note that they are 5mm thicker than the PZ490 halves on the right. Our 2-stroke expert Neels van Niekerk requested this to improve power delivery past peak power at 8300rpm, this will be very useful if one of my runs next year picks up a bit of tail wind to allow the engine to keep on delivering decent power and get me (hopefully!) to that world record!”

The first casing taking shape, the flat piece towards the camera is where the barrel will bolt on. I know most of us have seen this type of milling before but it’s just never been this personal and exciting before!

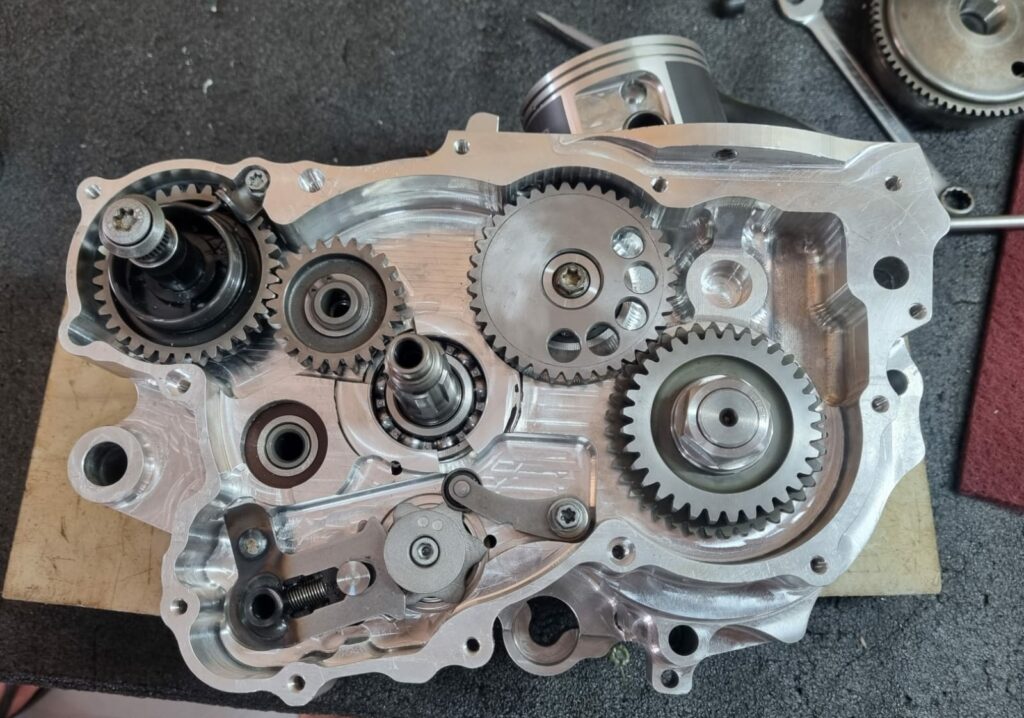

The crank was built thanks to the amazing engineering work done by P&C Technologies! We managed to get it to total runout of only 0.03mm after a couple of minutes, great stuff for such a whopping big crank.

Another step forward for PZ490, machining of our barrel in the power valve area was completed by Rost Engineering. The piston is for a CR500 Honda.

This is a busy engine and it kept us on our toes, a couple of small issues were ironed out and we feel confident of a first start in the next 2 weeks. The Roof of Africa bike uses gears from from a KTM 300 engine.

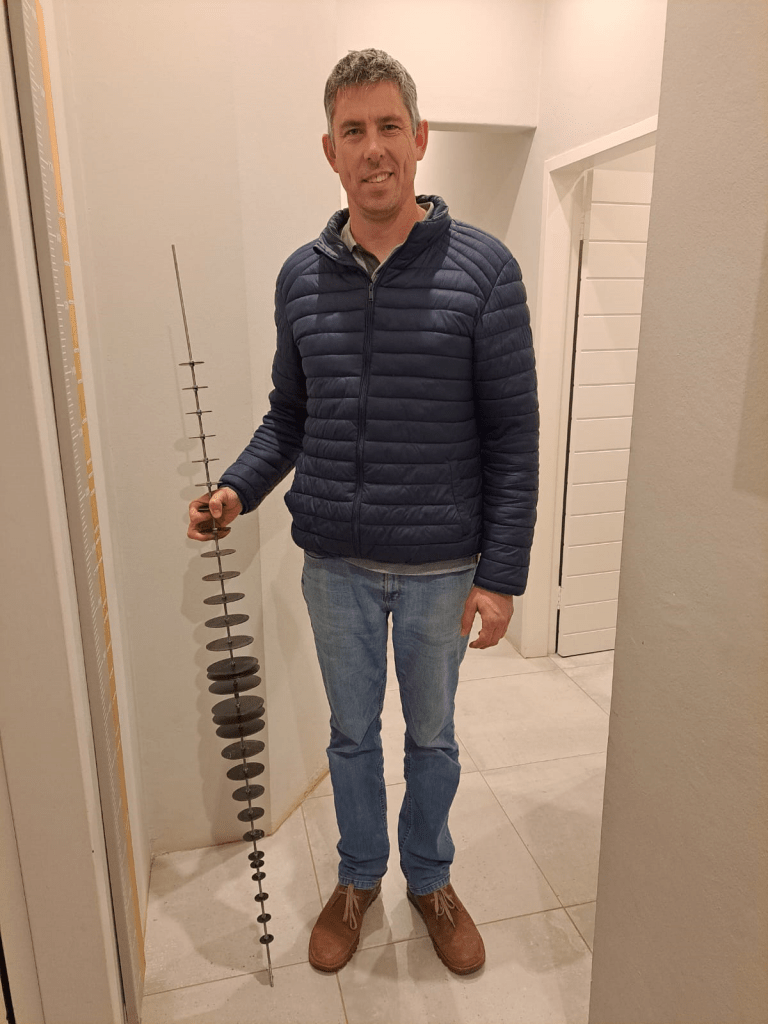

Riempies is the nickname for Riaan Pretorius, the man who is going to wrestle this bike through the rocks at Roof 2023. He’s a tall, skinny looking guy that never gives up, hence we started calling him Riempies some years ago.

Ready for action. now its just to slot he engine int the KTM 300 frame, fit that pipe and start her up!

The big launch / first ride with PZ490 will take place next weekend. Watch this spot and our socials – and we sure look forward to seeing Riempies on the rocks in Lesotho…

www.matjien.com