There are so many “Mom and Pop” businesses in the motorcycle trade that just quietly go about delivering great products and service. Savage Graphics Lab on the East Rand is one of those companies…

There is nothing quite as lekker as a fresh set of plastics on your dirtbike, complimented with your own custom design. That’s what Grant Frerichs gets up to. They don’t do off the shelf kits, you tell them what you need, which logo’s you want and all that and he’ll custom design and produce it all for you.

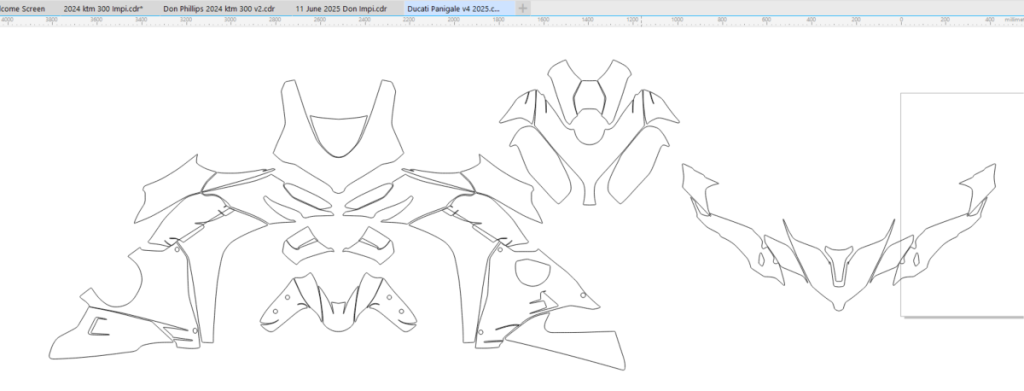

“It’s a process”, he explains “That starts with the correct template for your specific machine” – and of those he has a variety – and if he doesn’t have the template, he draws it up for you.

“We do pretty much anything you like that has to do with any kind of motorcycle from factory stock, right up to the funkiest design and colourways that you can think of. While Dirtbikes are a big part of our business, Superbikes are exactly the same process and we do some pretty awesome stuff.”

“Once the template is correct, then the design work happens, correct colours and logo’s to the clients specifications. Proofs are sent off so that customers can have a looksee and once the designs are approved, the manufacturing process starts.”

The base of the design gets printed onto what is basically a huge sticker – roughly the size of your average dinner table. That includes decals for all the bits from your side covers, tank shrouds, fuel tank, tailpiece and so-on. “The most important factor with decal kits is the material that you use and the best quality stuff is imported from the USA.”

A clear laminate is applied over the base material by a giant roller. This keeps it all strong and helps to prevent the finished product from getting scuffed. It’s amazing what is available:

Would you like clear or gloss? would you like gold flecks in your decal kit? Just ask. The ones being done on this day were covered in gloss which really makes the colours jump.

From the laminating table, the sheet is placed back into the printing machine which automatically reads all the bleed marks and cutting lines. A heat process ensures that the laminate bonds to the sticker correctly and then it proceeds to apply tear out lines along each individual sticker. Technology is just too clever.

Once the cut lines are done, the sheet is left for 48 hours in order to cure properly. “By allowing it to cool and cure, the stickers will not separate. If you rush the process, you get a sub-standard finished product.”

The final step is to remove each sticker. An Olfa blade just rounds it all off nicely for that perfect fit and the stickers are packaged for delivery.

Cool Huh!?

You then have the privilege of applying the decals to your bike.

TIP: Make sure that the plastics are clean with no trace of oily residue – and a heat gun is your friend or – if you wish, they will do it for you.

Neat, tidy, efficient and a very cost effective way to freshen up any machine.

The Savage Graphics Lab is in Kempton Park on the East Rand. Wrap anything you like!

They also do custom branding on tee shirts, caps, riding shirts, custom seats…